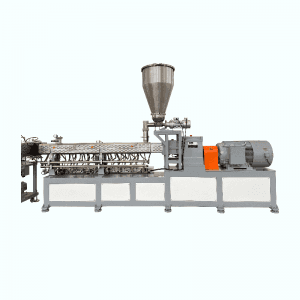

clamshell tong minyak extruder

PSHJ clamshell tong minyak Co-puteran extruder kembar meneng

Tong minyak bisa dibukak ing menit. Iki ndadekake Éwah-éwahan produk, pangopènan lan riset gampang lan cepet. Loro-lorone ngawut-awut lan barel dirancang nggunakake prinsip bangunan pemblokiran.

Modular construction

Seri XINDA PSHJ kembar meneng sing dibangun ing sistem modul. Ing kauntungan utama saka Desain modul iki konfigurasi Versatile. Tugas Processing bisa f tuntas karo mung sawetara tong minyak lan meneng variasi.

Barrel section- Dhewe kontrol

Ing asas modul saka tong minyak ijin urutan pas kanggo saben aplikasi. Suhu saben bagean tong minyak kang bisa nyetel dhewe. Meriam mesin ingkang ndamel benter Listrik nyedhiyani kanggo panas, cooling wis dijupuk karo banyu.

barel Standard

Urutan dipilih bebas saka ngawut-awut lan unsur kneading njamin bagean proses kawin proses konfigurasi. Mangkono, zona proses beda bisa nyiyapake interchangeably, miturut syarat kanggo: ngaturaken; Plasticizing; Nyawiji lan mbathili; homogenizing; degassing; Meksa bangunan.

Aplikasi:

1. Various plastik ngisi anorganik, campuran Polymer (alloy plastik), pewarna plastik, etc.

2. Various plastik ngisi anorganik, campuran Polymer (alloy plastik), pewarna plastik, etc.

3. Various engineering pitulungan plastik saka serat kaca, pelet semangat-retardant

4. Various antibacterial, terisolasi, bahan toughening Efesus tartamtu

5. Light / biologi bahan degradable film, asylum plastik degradable lan multi-fungsi bahan film anti-pedhut, etc.

6. materi spesifik kanggo otomotif lan perabot rumah tangga lan bahan kabel, etc.

7. elastomers Thermoplastic, kayata TPR, TPE, lan SBS, etc.

8. regenerate pelet kanggo PVC airproof bêsik, Thermo-telat lim, etc.

| model | PSHJ-20 | PSHJ-35 | PSHJ-50 | PSHJ-65 | PSHJ-75 | PSHJ-95 |

| Meneng Diameter: MM | Φ21.7 | Φ35.6 | Φ50.5 | Φ62.4 | Φ71 | Φ91 |

| Central Distance | 18 | 30 | 42 | 52 | 60 | 102 |

| Length Diameter rasio | 28-52 | 28-52 | 28-52 | 28-52 | 28-52 | 28-52 |

| Main Motor Power | 4-5.5 | 22-45 | 75-110 | 110-185 | 160-280 | 180-355 |

| Max. Meneng Speed: RPM | 600 | 600 | 600 | 600 | 600 | 600 |

| Output torsi saben batang Nm | 32-43 | 175-358 | 597-875 | 875-1472 | 1273-2228 | 1365-2825 |

| Reference Output: KG / JAM | 5-20 | 20-80 | 80-200 | 150-350 | 300-600 | 800-1500 |

| model | C-PSHJ-35 | C-PSHJ-50 | C-PSHJ-65 | C-PSHJ-75 |

| Meneng Diameter: MM | Φ35.6 | Φ50.5 | Φ62.4 | Φ71 |

| Central Distance | 30 | 42 | 52 | 60 |

| Length Diameter rasio | 28-52 | 28-52 | 28-52 | 28-52 |

| Main Motor Power | 22-45 | 75-132 | 110-250 | 160-355 |

| Max. Meneng Speed: RPM | 800 | 800 | 800 | 800 |

| Output torsi saben batang Nm | 131-269 | 448-788 | 657-1492 | 955-2119 |

| Reference Output: KG / JAM | 150-300 | 200-500 | 400-800 | 500-100 |

Aplikasi saka Twin Meneng Extruder :

- Various ngisi plastik anorganik, Polymer campuran (alloy plastik), pewarna plastik, ECT

- Various engineering pitulungan plastik saka serat kaca, pelet semangat-retartant

- Various antibacterial, terisolasi, bahan toughening Efesus tartamtu

- Cahya / biologi bahan film degradable, amylum plastik degradable lan multi-fungsi bahan film anti-pedhut, etc.

- materi tartamtu kanggo otomotif lan perabot rumah tangga lan bahan kabel, etc

- elastomers Themoplastic, kayata TPR, TPE, lan SBS, etc

- pelet regenerate kanggo PVC airproof bêsik, lim Thermo-telat, etc

|

model

|

PSHJ-20

|

PSHJ-35

|

PSHJ-50

|

PSHJ-65

|

PSHJ-75

|

PSHJ-127

|

|

Meneng Diameter:

MM |

21.7

|

35,6

|

50,5

|

62,4

|

71

|

126

|

|

Central Distance

|

18

|

30

|

42

|

52

|

60

|

102

|

|

Length Diameter rasio

|

28-52

|

28-52

|

28-52

|

28-52

|

28-52

|

28-52

|

|

Main Motor Power

|

4-5.5

|

22-45

|

75-110

|

110-185

|

160-280

|

90-160

|

|

Max.Screw Speed:

RPM |

600

|

600

|

600

|

600

|

600

|

600

|

|

Output torsi saben batang: Nm

|

32-43

|

175-358

|

597-875

|

875-1472

|

1273-2228

|

850-1528

|

|

Reference Output: KG / JAM

|

5-20

|

20-80

|

80-200

|

150-350

|

300-600

|

800-1500

|

|

Max.Screw Speed:

RPM |

800

|

800

|

800

|

800

|

500

|

|

model

|

C-PSHJ-35

|

C-PSHJ-50

|

C-PSHJ-65

|

C-PSHJ-75

|

C-PSHJ-127

|

|

Meneng Diameter:

MM |

35,6

|

50,5

|

62,4

|

71

|

126

|

|

Central Distance

|

30

|

42

|

52

|

60

|

102

|

|

Length Diameter rasio

|

28-52

|

28-52

|

28-52

|

28-52

|

13-18

|

|

Main Motor Power

|

22-45

|

75-132

|

110-250

|

160-355

|

90-160

|

|

Output torsi saben batang: Nm

|

131-269

|

448-788

|

657-1492

|

955-2119

|

850-1528

|

|

Reference Output: KG / JAM

|

150-300

|

200-500

|

400-800

|

500-100

|

800-1500

|