Low MOQ for China Plastic Compounding Machine in PP/PE Colour Master Batch Compounding Machines

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by providing worth added design and style, world-class producing, and repair capabilities for Low MOQ for China Plastic Compounding Machine in PP/PE Colour Master Batch Compounding Machines, Our company concept is honesty, aggressive, realistic and innovation. With your assistance, we will grow much improved.

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by providing worth added design and style, world-class producing, and repair capabilities for China Masterbatch Compounding Line, Parallel Twin Screw Extruder, Due to our good goods and services, we’ve got received good reputation and credibility from local and international customers. If you want more information and are interested in any of our solutions, remember to feel free to contact us. We look forward to becoming your supplier in the near future.

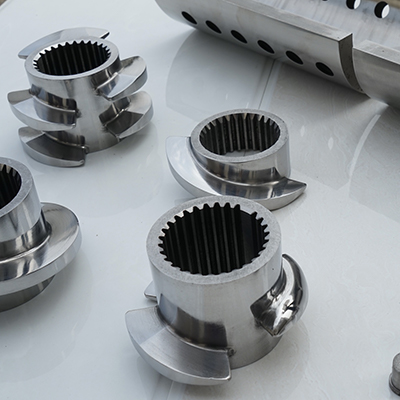

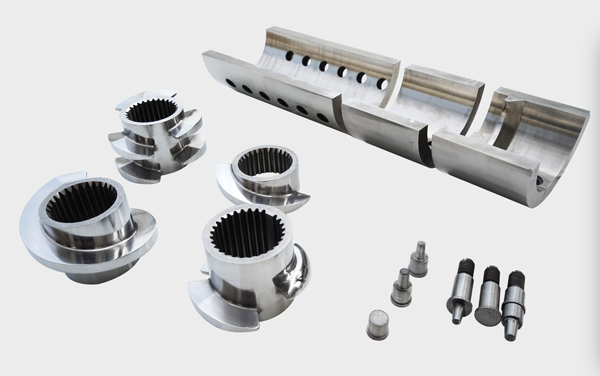

spare parts for co-kneader

jiangsu xinda tech limited specialized in the manufacture of co-kneader modular screw shaft, screw elements, barrel, and pins relating to various types that lies between ø30mm to ø200mm. we had several sets of advanced cnc machines and special processing equipment for manufacturing all these spare parts.

meanwhile, we also supply some spare parts for customer’s buss co-kneader and x-compound co-kneader according to customer’s requirements

xinda co-kneader screw elements, pins and barrel

| Xinda Co-kneader | Screw elements | Barrel | Pins | |

| SJW-45 | As per xinda drawing | As per xinda drawing | As per xinda drawing | |

| SJW-70 | As per xinda drawing | As per xinda drawing | As per xinda drawing | |

| SJW-100 | As per xinda drawing | As per xinda drawing | As per xinda drawing | |

| SJW-140 | As per xinda drawing | As per xinda drawing | As per xinda drawing | |

| SJW-200 | As per xinda drawing | As per xinda drawing | As per xinda drawing |

Application of the Twin Screw Extruder:

- Various plastic inorganic filler, polymer blending (plastic alloy), plastic coloring, ect

- Various engineering plastic reinforcement of glass fiber, flame-retartant pellets

- Various antibacterial, insulated, toughening materials for specific uses

- Light/biology degradable film materials, amylum degradable plastics and multi-functional anti-fog film materials, etc.

- Specific material for automobiles and household appliance and cable materials, etc

- Themoplastic elastomers, such as TPR, TPE, and SBS, etc

- Regenerate pellets for PVC airproof pieces, thermo-soluble glue, etc

|

Model

|

PSHJ-20

|

PSHJ-35

|

PSHJ-50

|

PSHJ-65

|

PSHJ-75

|

PSHJ-127

|

|

Screw Diameter:

MM |

21.7

|

35.6

|

50.5

|

62.4

|

71

|

126

|

|

Central Distance

|

18

|

30

|

42

|

52

|

60

|

102

|

|

Length Diameter Ratio

|

28-52

|

28-52

|

28-52

|

28-52

|

28-52

|

28-52

|

|

Main Motor Power

|

4-5.5

|

22-45

|

75-110

|

110-185

|

160-280

|

90-160

|

|

Max.Screw Speed:

RPM |

600

|

600

|

600

|

600

|

600

|

600

|

|

Output Torque per Shaft:N.m

|

32-43

|

175-358

|

597-875

|

875-1472

|

1273-2228

|

850-1528

|

|

Reference Output: KG/HOUR

|

5-20

|

20-80

|

80-200

|

150-350

|

300-600

|

800-1500

|

|

Max.Screw Speed:

RPM |

800

|

800

|

800

|

800

|

500

|

|

Model

|

C-PSHJ-35

|

C-PSHJ-50

|

C-PSHJ-65

|

C-PSHJ-75

|

C-PSHJ-127

|

|

Screw Diameter:

MM |

35.6

|

50.5

|

62.4

|

71

|

126

|

|

Central Distance

|

30

|

42

|

52

|

60

|

102

|

|

Length Diameter Ratio

|

28-52

|

28-52

|

28-52

|

28-52

|

13-18

|

|

Main Motor Power

|

22-45

|

75-132

|

110-250

|

160-355

|

90-160

|

|

Output Torque per Shaft:N.m

|

131-269

|

448-788

|

657-1492

|

955-2119

|

850-1528

|

|

Reference Output: KG/HOUR

|

150-300

|

200-500

|

400-800

|

500-100

|

800-1500

|