Newly Arrival China Plastic HDPE Rib Reinforced Spiral Sewage Pipe Extrusion Line

Our growth depends over the superior equipment ,outstanding talents and continuously strengthened technology forces for Newly Arrival China Plastic HDPE Rib Reinforced Spiral Sewage Pipe Extrusion Line, Our merchandise are widely recognized and dependable by users and can meet continuously building economic and social needs.

Our growth depends over the superior equipment ,outstanding talents and continuously strengthened technology forces for China Extrusion Line, Pipe Extrusion Line, Our company regards “reasonable prices, high quality,efficient production time and good after-sales service” as our tenet. We hope to cooperate with more customers for mutual development and benefits in future. Welcome to contact us.

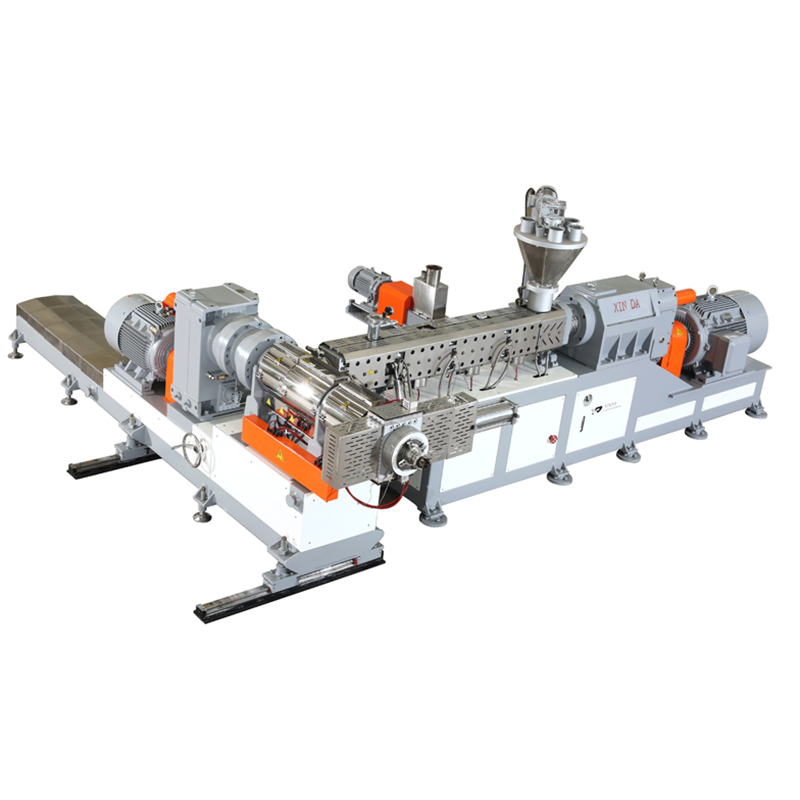

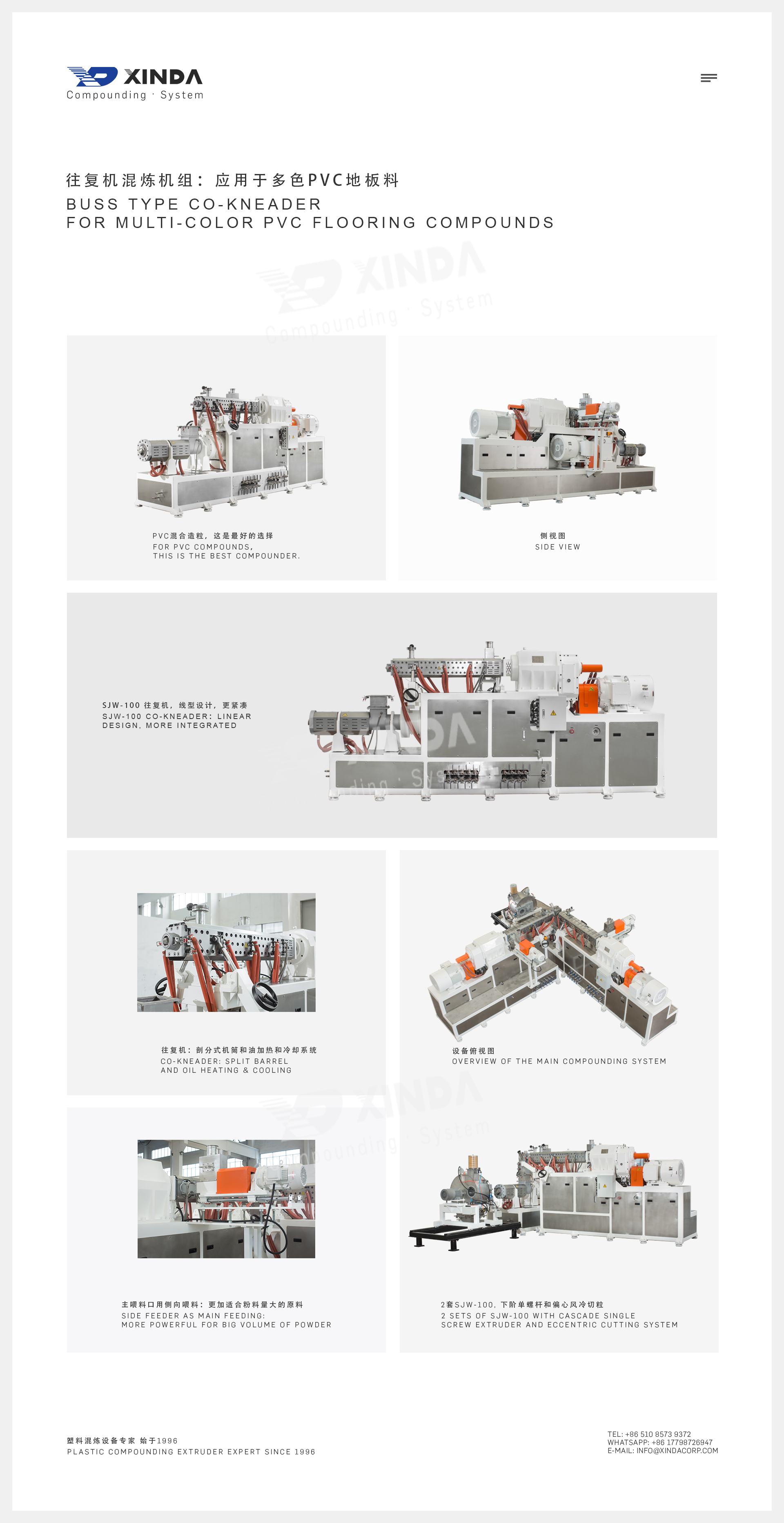

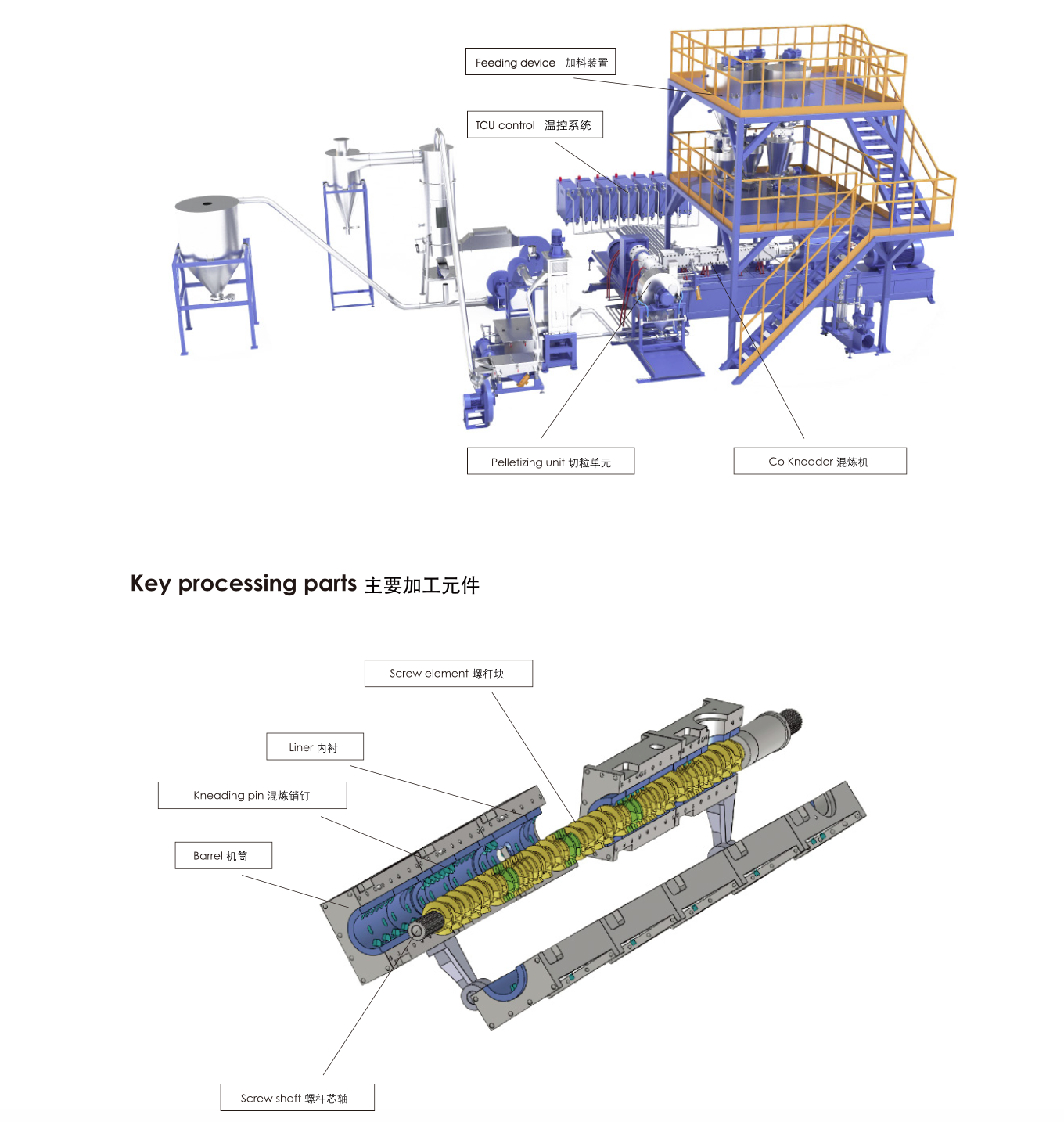

XINDA Co-Kneader family

SJW(M) System

SJW(C) System

SJW(T)System

SJW(M) System

Melt pump is installed between the main extruder and the die. The benefits of melt pumps for extrusion operations includes the elimination of surging and other fluctuations, reduction of inconsistent melt temperatures, high pressures at lower product temperatures, compensation for the pumping or mixing capacity of the extruder, possibly reduced start-up times, and reduction of energy required by the extruder

Application:

–Color masterbatch/ Concentrates

–High loading filler masterbatch

–Hot-melt adhesive

–Engineering plastics compounding

–Engineered elastomers

|

Model |

SJW-45(M) |

SJW-70(M) |

SJW-100(M) |

SJW-140(M) |

|

Screw Diameter (MM) |

45 |

70 |

100 |

140 |

|

Length Diameter Ratio |

15-25 |

15-25 |

15-25 |

15-25 |

|

Main Motor Power (KW) |

15-30 |

55-75 |

90-132 |

160-220 |

|

Max. Screw Speed (RPM) |

500 |

500 |

500 |

500 |

|

Reference Output (KG/HOUR) |

40-50 |

150-200 |

300-400 |

800-1000 |

SJW(C) System

The cascade type of Co-Kneader compounding line is consisted of Co-Kneader main machine and another large size single screw extruder. The stock will fall into the second stage single screw extruder after fully dispersed and distributed in Co-Kneader. It will ensure the materials are processed at lower temperature with the stable extruding The whole process is divided into two parts. Co-Kneader is in charge of kneading while the second stage single screw is focusing on extruding The cascade system is very helpful to achieve the better final quality.

Application:

–PVC compounding pelletizing

–Shoe sole compounds

–Wire cable compounds (XLPE, HFFR, Semi-conductive compounds, etc)

–Concentrated color masterbatch

–Rubber, Final-batch rubber, Master batch, Mixed compound

–Elastomers

–Bio-degradable compounds

–Metal injection molding

|

Model |

SJW-45(C) |

SJW-70(C) |

SJW-100(C) |

SJW-140(C) |

SJW-200(C) |

|

Screw Diameter (MM) |

45 |

70 |

100 |

140 |

200 |

|

Length Diameter Ratio |

20~25 |

20~25 |

20~25 |

20~25 |

20~25 |

|

Main Motor Power (KW) |

15~30 |

55~75 |

90~132 |

160~300 |

350~550 |

|

Second-stageScrew Diameter (MM) |

60 |

120 |

150 |

200 |

280 |

|

Second-stage L/D |

7~8 |

7~8 |

7~8 |

7~8 |

7~8 |

|

Second-stage Power (KW) |

15~22 |

37~45 |

55~75 |

90~110 |

132~160 |

|

Max.Screw Speed (RPM) |

500 |

500 |

500 |

500 |

500 |

|

Reference Output (KG/HOUR) |

40~70 |

150~250 |

300~500 |

800~1200 |

1900~3600 |

SJW(T)System

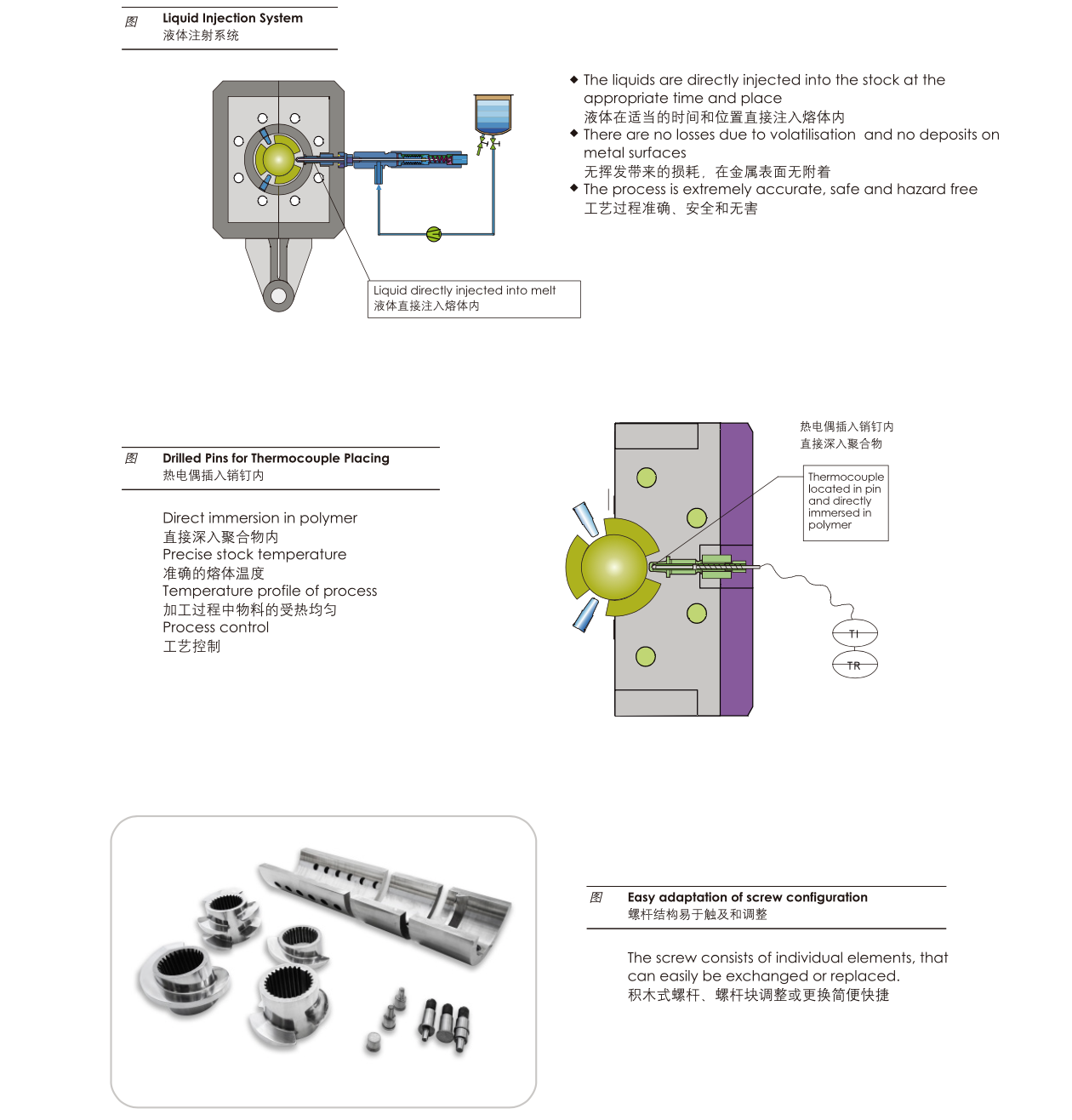

With the special working principle and shorter L/D ratio of XINDA Co-Kneader enjoys wide application in the field of thermoset plastics compounds and powder coating. Thermocouples can be mounted in drilled kneading pins at various different points along the process section to get the direct contact with the melt. The combination of a liquid heating and cooling system and an extremely precise monitoring of the melt

temperature makes Co-Kneader a very successful solution in thermoset plastics compounds and powder coating toner.

Application:

–Thermoset plastics

–Powder coating and toner

–Bakelite molding compounds

–Polymer: epoxy, acrylic, urethane, polyster, etc

|

Model |

SJW-45(T) |

SJW-70(T) |

SJW-100(T) |

SJW-140(T) |

SJW-200(T) |

|

Screw Diameter (MM) |

45 |

70 |

100 |

140 |

200 |

|

Length Diameter Ratio |

7-15 |

7-15 |

7-15 |

7-15 |

7-15 |

|

Main Motor Power (KW) |

15-30 |

55-75 |

90-132 |

160-220 |

350-450 |

|

Max. Screw Speed (RPM) |

500 |

500 |

500 |

500 |

500 |

|

Reference Output (KG/HOUR) |

40-100 |

100-400 |

300-600 |

500-1000 |

1000-2000 |

Description For Products

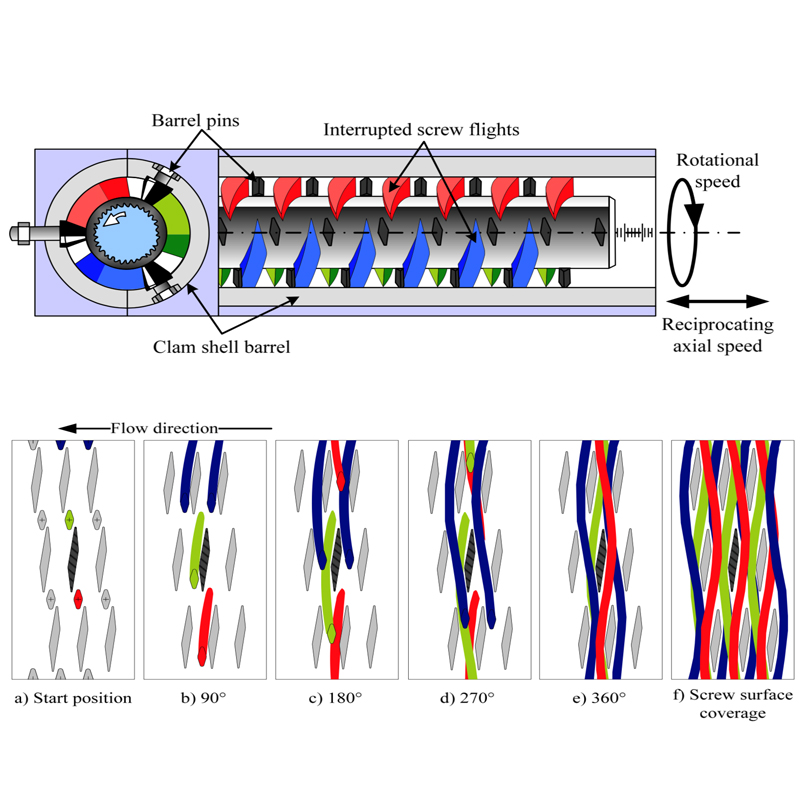

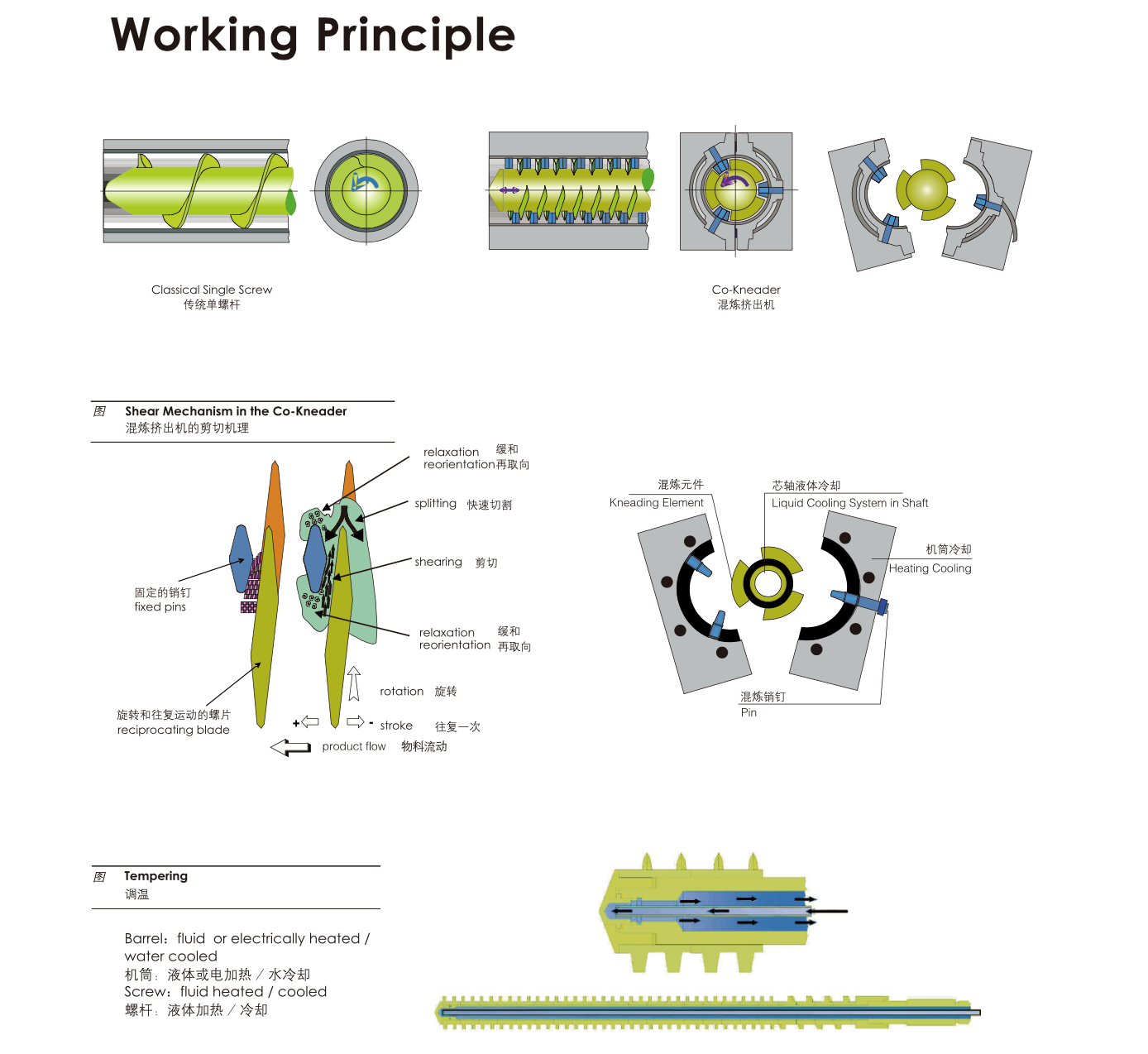

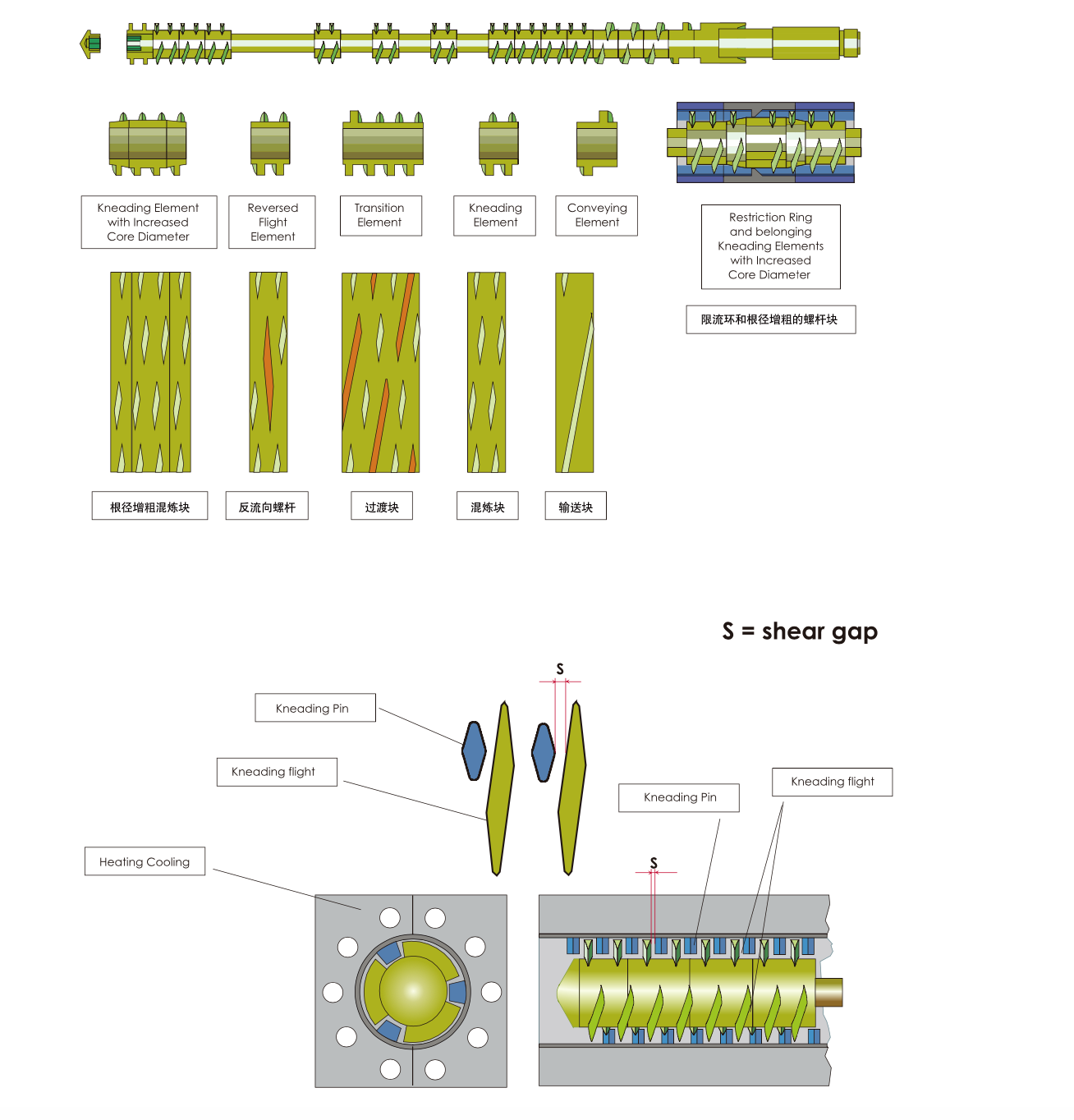

Working Principle For Co-kneader

Advantage For Four Flights Co-kneader

Feature

Feature

- –Lower energy input, lower melt temperatures

- –Extremely homogeneous mixing, no shear spikes, equal treatment of polymer matrix

- –High degree of self-wiping and have no dead spot

- –Dispersive mixing without destroying delicate fllers

- –High volumetric loadings of fllers and additives

- –Efficient blending of liquid components

- –Broad application for compounding without changing hardware

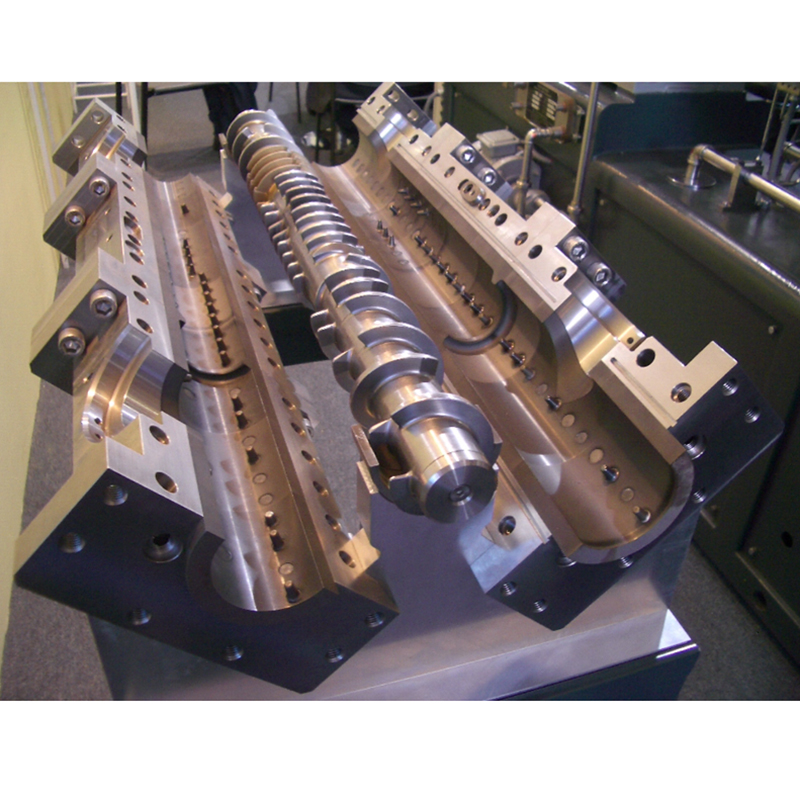

- –Axially opened split barrel guarantees ease of cleaning and fast maintenance

- –Replacement parts, such as screws, barrel lining and pins can be changed individually

Factory Introduction

Application of the Twin Screw Extruder:

- Various plastic inorganic filler, polymer blending (plastic alloy), plastic coloring, ect

- Various engineering plastic reinforcement of glass fiber, flame-retartant pellets

- Various antibacterial, insulated, toughening materials for specific uses

- Light/biology degradable film materials, amylum degradable plastics and multi-functional anti-fog film materials, etc.

- Specific material for automobiles and household appliance and cable materials, etc

- Themoplastic elastomers, such as TPR, TPE, and SBS, etc

- Regenerate pellets for PVC airproof pieces, thermo-soluble glue, etc

|

Model

|

PSHJ-20

|

PSHJ-35

|

PSHJ-50

|

PSHJ-65

|

PSHJ-75

|

PSHJ-127

|

|

Screw Diameter:

MM |

21.7

|

35.6

|

50.5

|

62.4

|

71

|

126

|

|

Central Distance

|

18

|

30

|

42

|

52

|

60

|

102

|

|

Length Diameter Ratio

|

28-52

|

28-52

|

28-52

|

28-52

|

28-52

|

28-52

|

|

Main Motor Power

|

4-5.5

|

22-45

|

75-110

|

110-185

|

160-280

|

90-160

|

|

Max.Screw Speed:

RPM |

600

|

600

|

600

|

600

|

600

|

600

|

|

Output Torque per Shaft:N.m

|

32-43

|

175-358

|

597-875

|

875-1472

|

1273-2228

|

850-1528

|

|

Reference Output: KG/HOUR

|

5-20

|

20-80

|

80-200

|

150-350

|

300-600

|

800-1500

|

|

Max.Screw Speed:

RPM |

800

|

800

|

800

|

800

|

500

|

|

Model

|

C-PSHJ-35

|

C-PSHJ-50

|

C-PSHJ-65

|

C-PSHJ-75

|

C-PSHJ-127

|

|

Screw Diameter:

MM |

35.6

|

50.5

|

62.4

|

71

|

126

|

|

Central Distance

|

30

|

42

|

52

|

60

|

102

|

|

Length Diameter Ratio

|

28-52

|

28-52

|

28-52

|

28-52

|

13-18

|

|

Main Motor Power

|

22-45

|

75-132

|

110-250

|

160-355

|

90-160

|

|

Output Torque per Shaft:N.m

|

131-269

|

448-788

|

657-1492

|

955-2119

|

850-1528

|

|

Reference Output: KG/HOUR

|

150-300

|

200-500

|

400-800

|

500-100

|

800-1500

|