Recently, Xinda has taken several orders, providing Compounding extruder lines for EPP micro pellets by Strand cutting system & Underwater cutting system both. Extruding mold, water trough, air knife and pelletizer, all of them are with special design. While for twin screw extruder, our customers chose Clamshell barrel design, which is ease of cleaning, and suitable for their various color EPP requirements.

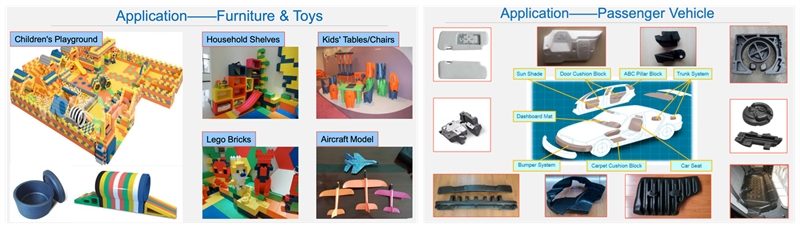

EPP (Expanded Polypropylene) are now widely used in automobile, electronic packaging, transport packaging, civilian & leisure, mariculture, military and other fields. HTEC is researching steam-saving and molding- time-saving products while controlling them in specific density ranges between 10 g/L and 250 g/L.

Now Xinda gathered much experience on EPP micro pellet production, any interest, please feel free to contact us.

Post time: Jun-05-2020