-

Multi-color PVC Flooring Compounds Kneading Extruder System

LOW SHEAR, LOW PRESSURE, LOW TEMPERATURE BUT HIGH KNEADING EFFICIENCY FOR YOUR COMPOUNDING NEEDS -

Lab Micro Compounder Twin Screw Extruder 35mm Pelletizing For Masterbatch Testing

Xinda has twin screw extruder & co-kneader extruder for Lab application,which used for masterbatches,pvc compounding,filler masterbatches testing,ect -

High Concerntrated Color Masterbatches Compounding Making Machine With Four Flights Screw

Description For Products Application For Co-kneader Output For Reference Layout for HFFR working process Output For Reference Model SKW-85 SKW-105 SKW-125 Co-kneader Screw Diameter 85 105 125 L/D Ratio 15-22 15-22 15-22 Max.Motor Power 600 600 600 Main Motor Power 110-160 200-280 350-450 Second-stage Screw Diameter 150 180 220 Second-stage Screw L/D Ratio 7 7 7 Max.Screw Speed 60 60 60 Second-stage Motor Power 55 75 110 Reference Output(KG) SKW-85 SKW-105 SKW-125 ... -

Concentrates Masterbatch Compounding Extruder And Pelletizing Line

XINDA Co-Kneader family SJW(M) System SJW(C) System SJW(T)System SJW(M) System Melt pump is installed between the main extruder and the die. The benefits of melt pumps for extrusion operations includes the elimination of surging and other fluctuations, reduction of inconsistent melt temperatures, high pressures at lower product temperatures, compensation for the pumping or mixing capacity of the extruder, possibly reduced start-up times, and reduction of energy required by the extruder Applic... -

Four Flights Co-Kneader Compound Extruder for HFFR or XLPE

XINDA develops latest new technology with 4 flights. The XINDA SKW Kneader each spiral is broken by four gaps per revolution to locate the kneading flights. Four rows of kneading pins, which are individually inserted in the barrel per 90 degree, are intermeshed with these flights. With the same L/D ratio, it achieves more mixing, but less friction heat. The reciprocating wobble-box synchronizes the shaft rotation and oscillation so that each revolution of the screw is accompanied by one full stroke forward and backwards. This ensures optimal distributive and dispersive mixing with minimal energy consumption. -

Biodegradable Corn Starch Twin Screw Extruder Machine PLA Pellet Plastic Making Machine

The barrel of Twin Screw Extruder can be opened in minutes. This makes product changeover, maintenance and research fast and easy. Both screws and barrels are designed using the building block principle. The screw configuration, barrel setup, feeding and venting, screen changing, way of pelletizing and process requirements, in consideration of the machine's versatility in other general applications.

-

UNDERWATER PELLETIZER

Relatively low priced dosing system.Accurate dosing cylinder. Stepper motor speed starting from 0.1 up to 200 rpm.A volumetric feeder, on the other hand, does this based on volume in speed. -

spare parts for Co-kneader

we also supply some spare parts for customer’s buss co-kneader and x-compound co-kneader according to customer’s requirements.we had several sets of advanced cnc machines and special processing equipment for manufacturing all these spare parts. -

Lab-scale co-kneader

Screw diameter: 45mm L/D ratio: 10-25 Stroke: 6.75mm Main motor: 22KW Max. Screw speed: 500 RPM Reference output: 10-60kg/h -

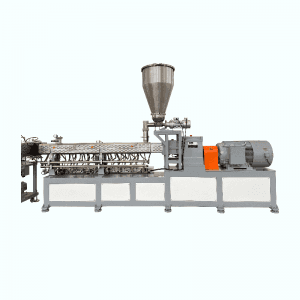

fixed barrel extruder

SHJ fixed barrel Co-rotating twin screw extruder

The XINDA SHJ twin screw series are built on a modular system. The major advantage of this modular design is the versatile configuration. Processing tasks can be optimally accomplished with only a few barrel and screw variations. -

clamshell barrel extruder

PSHJ Clamshell barrel Co-rotating twin screw extruder.The barrel can be opened in minutes. This makes product changeover, maintenance and research fast and easy. Both screws and barrels are designed using the building block principle. -

SKW 4-flight co-kneader

Four-flight Compounding System

Based on 3-flgiht compounding design, XINDA develops latest new technology with 4 flights. The XINDA SKW Kneader each spiral is broken by four gaps per revolution to locate the kneading flights. Four rows of kneading pins, which are individually inserted in the barrel per 90 degree, are intermeshed with these flights. With the same L/D ratio, it achieves more mixing, but less friction heat. The reciprocating wobble-box synchronizes the shaft rotation and oscillation so that each revolution of the screw is accompanied by one full stroke forward and backwards. This ensures optimal distributive and dispersive mixing with minimal energy consumption.

Send your message to us:

Write your message here and send it to us