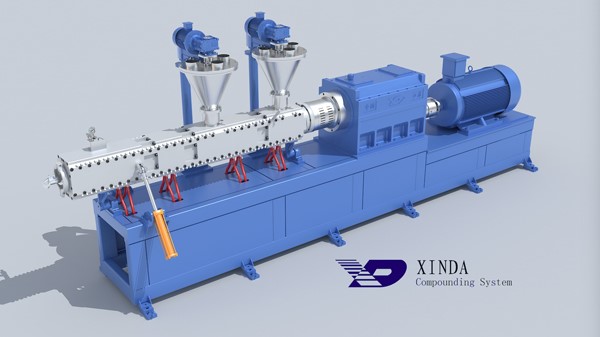

SKW 4-flight co-kneader

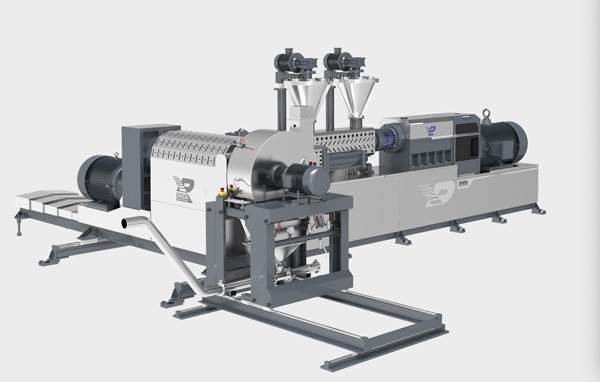

SKW 4-Flight Co-kneader Compounding System 4-flight Compounding System

Apat-flight Compounding System

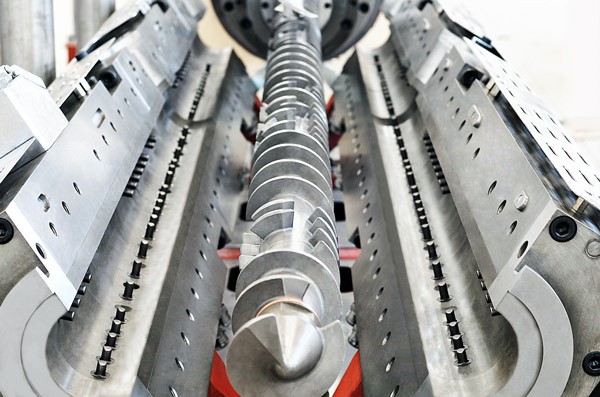

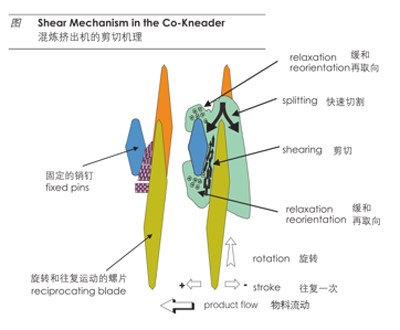

Batay sa 3-flgiht compounding disenyo, Xinda bubuo pinakabagong mga bagong teknolohiya na may 4 na flight. Ang Xinda SKW kneader bawat spiral ay nasira sa pamamagitan ng apat na gaps sa bawat rebolusyon upang mahanap ang pagmamasa flight. Apat na hanay na pagmamasa pin, na kung saan ay isa-isang nakapasok sa barrel per 90 degree, ay intermeshed sa mga flight. Gamit ang parehong L / D ratio, ito Nakakamit higit pang paghahalo, ngunit mas kaunting pagkikiskisan init. Ang reciprocating wobble-box Sini-synchronize ng ang pag-ikot baras at osilasyon upang ang bawat rebolusyon ng turnilyo ay sinamahan ng isang full stroke pasulong at paatras. Ito matiyak ang pinakamahusay na nagbabaha at nagpapakalat paghahalo may minimal na pagkonsumo ng enerhiya.

application

Cable Compounds: Masterbatches:

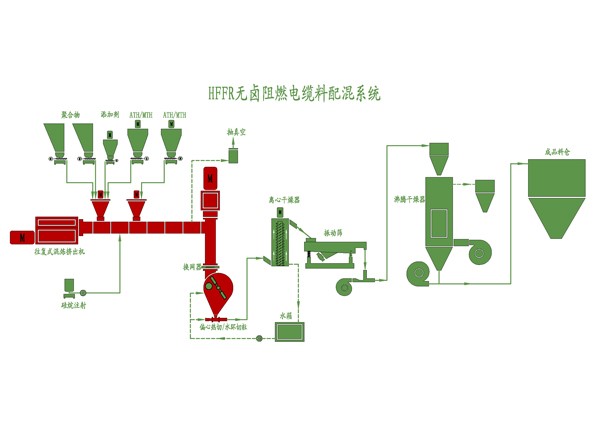

HFFR Mataas na puro kulay MB

XLPE Itim at puti MB

High load tagapuno MB

Semi-kondaktibo insulating PET / PP / PA fiber MB

Black sheathing Metal iniksyon paghuhulma

SKW Serial Four-flight Co-kneader

|

modelo |

SKW-85 |

SKW-105 |

SKW-125 |

|

Co-kneader Screw Diameter |

85 |

105 |

125 |

|

L / D Ratio |

15-22 |

15-22 |

15-22 |

|

Max. Maluwag ang tornilyo ng Bilis |

600 |

600 |

600 |

|

Main Motor Power |

110-160 |

200-280 |

350-450 |

|

Ikalawang yugto Screw Diameter |

150 |

180 |

220 |

|

Ikalawang yugto tornilyo L / D Ratio |

7 |

7 |

7 |

|

Max. Maluwag ang tornilyo ng Bilis |

60 |

60 |

60 |

|

Ikalawang yugto Motor Power |

55 |

75 |

110 |

|

reference Output |

SKW-85 |

SKW-105 |

SKW-125 |

|

HFFR Cable Compounds |

200-400 |

500-800 |

800-1500 |

|

Black sheathing |

200-400 |

500-800 |

800-1500 |

|

Semi-kondaktibo Insulating Compounds |

200-400 |

500-800 |

800-1500 |

|

Silane XLPE Cable Compounds |

200-400 |

500-800 |

800-1500 |

|

Mataas Concentrated Kulay MB |

150-350 |

400-700 |

700-1200 |

|

Carbon Black MB |

150-350 |

400-700 |

700-1200 |

|

Mataas Loaded Filler MB |

200-400 |

600-1000 |

900-1600 |

Application ng Twin Screw Extruder :

- Iba't-ibang mga plastic tulagay tagapuno, polimer blending (plastic haluang metal), plastic pangkulay, ect

- Iba't-ibang engineering plastic na pampalakas ng glass fiber, apoy-retartant pellets

- Iba't-ibang mga antibacterial, insulated, toughening materyales para sa partikular na mga paggamit

- Light / biology degradable film na materyales, amylum degradable plastik at multi-functional anti-fog film na materyales, at iba pa

- Tukoy na materyal para sa mga sasakyan at sambahayan appliance at cable materyales, etc

- Themoplastic elastomer, tulad ng TPR, TPE, at SBS, etc

- Regenerate pellets para sa PVC airproof piraso, thermo-natutunaw pandikit, atbp

|

modelo

|

PSHJ-20

|

PSHJ-35

|

PSHJ-50

|

PSHJ-65

|

PSHJ-75

|

PSHJ-127

|

|

Screw Diameter:

MM |

21.7

|

35.6

|

50.5

|

62.4

|

71

|

126

|

|

Central Distance

|

18

|

30

|

42

|

52

|

60

|

102

|

|

Haba Diameter Ratio

|

28-52

|

28-52

|

28-52

|

28-52

|

28-52

|

28-52

|

|

Main Motor Power

|

4-5.5

|

22-45

|

75-110

|

110-185

|

160-280

|

90-160

|

|

Max.Screw Speed:

RPM |

600

|

600

|

600

|

600

|

600

|

600

|

|

Output metalikang kuwintas sa bawat katawan ng poste: Nm

|

32-43

|

175-358

|

597-875

|

875-1472

|

1273-2228

|

850-1528

|

|

Reference Output: KG / HOUR

|

5-20

|

20-80

|

80-200

|

150-350

|

300-600

|

800-1500

|

|

Max.Screw Speed:

RPM |

800

|

800

|

800

|

800

|

500

|

|

modelo

|

C-PSHJ-35

|

C-PSHJ-50

|

C-PSHJ-65

|

C-PSHJ-75

|

C-PSHJ-127

|

|

Screw Diameter:

MM |

35.6

|

50.5

|

62.4

|

71

|

126

|

|

Central Distance

|

30

|

42

|

52

|

60

|

102

|

|

Haba Diameter Ratio

|

28-52

|

28-52

|

28-52

|

28-52

|

13-18

|

|

Main Motor Power

|

22-45

|

75-132

|

110-250

|

160-355

|

90-160

|

|

Output metalikang kuwintas sa bawat katawan ng poste: Nm

|

131-269

|

448-788

|

657-1492

|

955-2119

|

850-1528

|

|

Reference Output: KG / HOUR

|

150-300

|

200-500

|

400-800

|

500-100

|

800-1500

|