Top Suppliers China Factory Formula Research Small Double Screw Extruder

Our company since its inception, usually regards product high-quality as company life, constantly boost manufacturing technology, boost product excellent and continuously strengthen company total excellent administration, in strict accordance using the national standard ISO 9001:2000 for Top Suppliers China Factory Formula Research Small Double Screw Extruder, We will wholeheartedly welcome all purchasers within the industry each at your house and abroad to cooperate hand in hand, and develop a vibrant upcoming with each other.

Our company since its inception, usually regards product high-quality as company life, constantly boost manufacturing technology, boost product excellent and continuously strengthen company total excellent administration, in strict accordance using the national standard ISO 9001:2000 for China Twin Screw Extruder, Parallel Twin Screw Extruder, With more than 9 years of experience and a professional team, we have exported our products to many countries and regions all over the world. We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

Description For Products

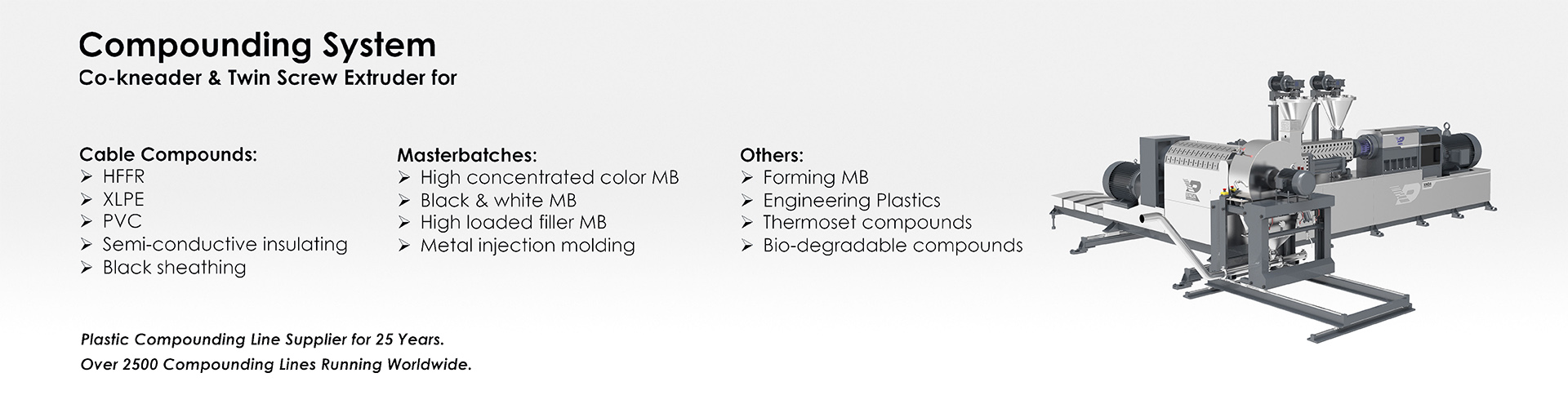

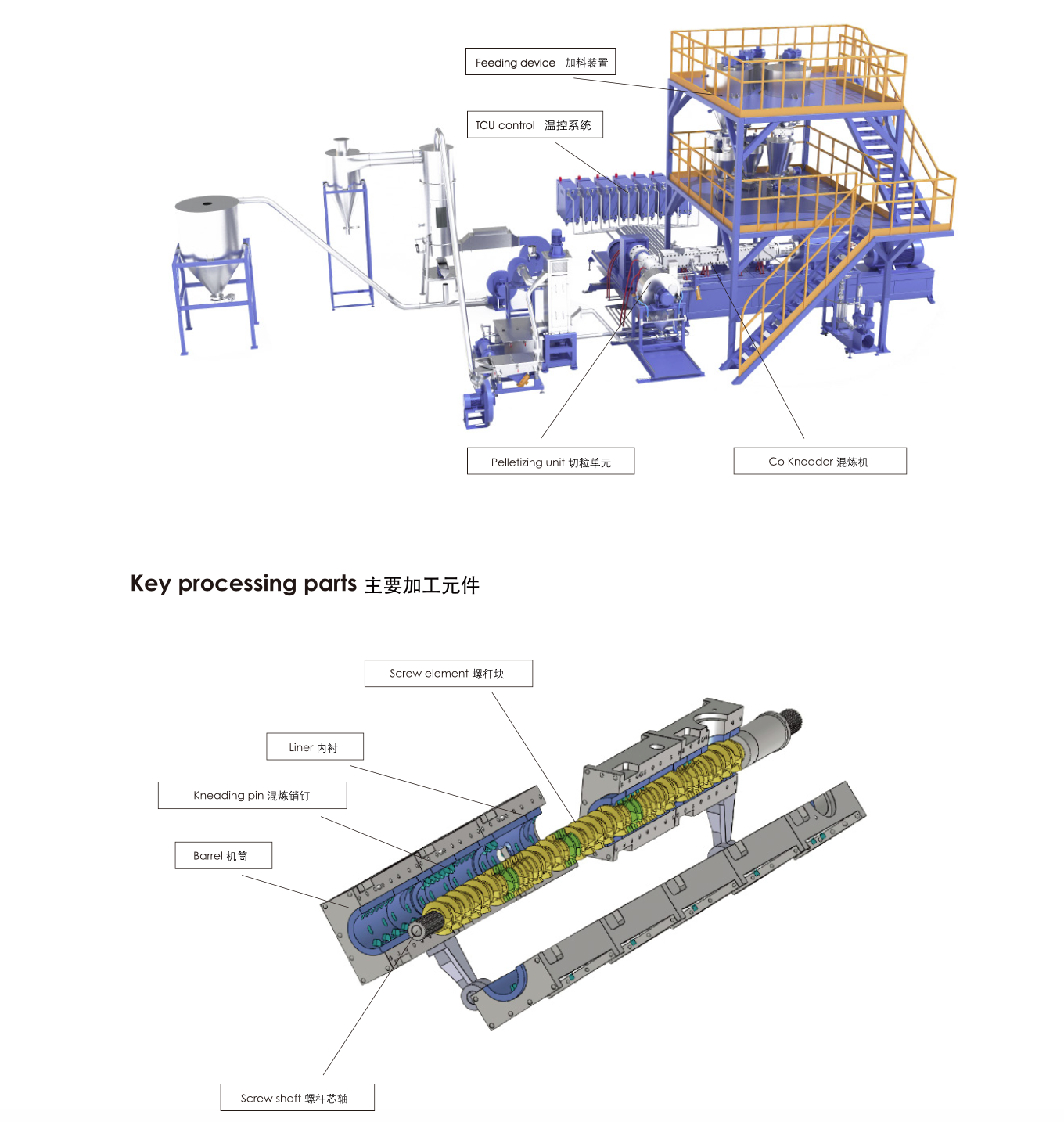

Application For Co-kneader

Output For Reference

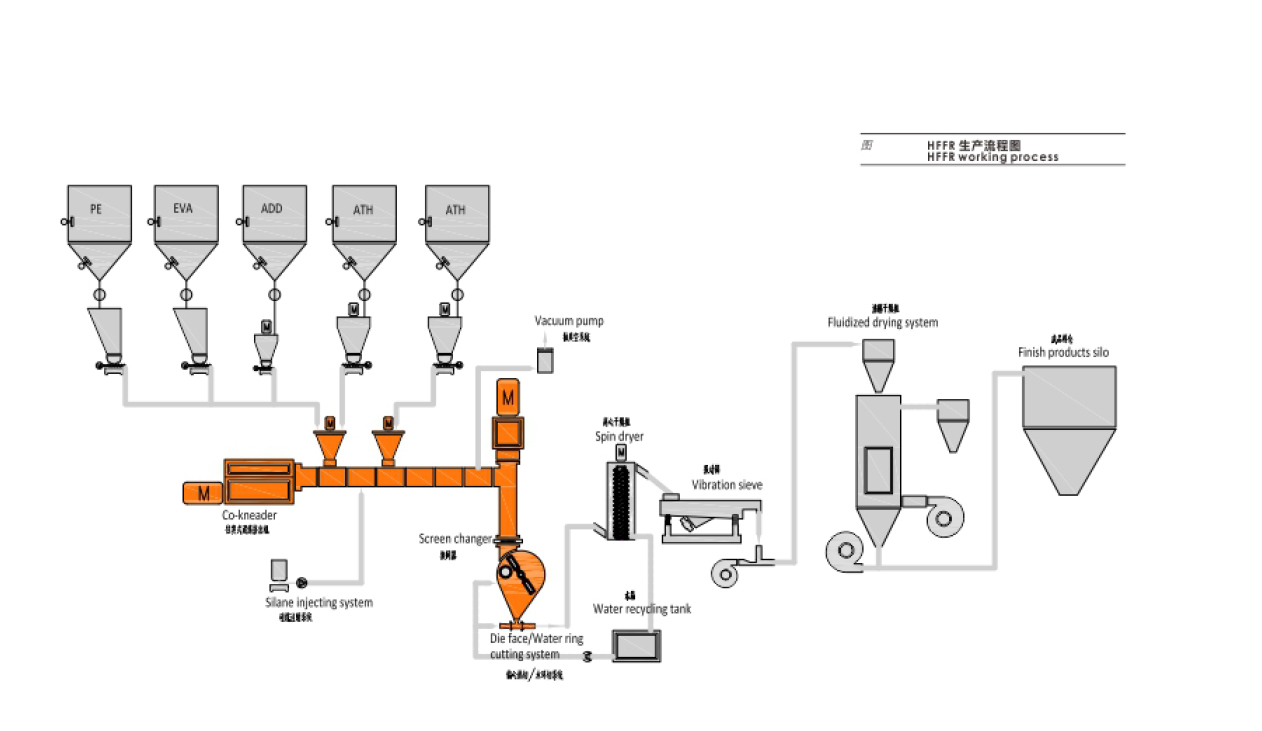

Layout for HFFR working process

Output For Reference

| Model | SKW-85 | SKW-105 | SKW-125 |

| Co-kneader Screw Diameter | 85 | 105 | 125 |

| L/D Ratio | 15-22 | 15-22 | 15-22 |

| Max.Motor Power | 600 | 600 | 600 |

| Main Motor Power | 110-160 | 200-280 | 350-450 |

| Second-stage Screw Diameter | 150 | 180 | 220 |

| Second-stage Screw L/D Ratio | 7 | 7 | 7 |

| Max.Screw Speed | 60 | 60 | 60 |

| Second-stage Motor Power | 55 | 75 | 110 |

| Reference Output(KG) | SKW-85 | SKW-105 | SKW-125 |

| HFFR Cable Compounds | 200-400 | 500-800 | 800-1500 |

| Black sheathing | 200-400 | 500-800 | 800-1500 |

| Semi-conductive Insulating Compounds | 200-400 | 500-800 | 800-1500 |

| Silane XLPE Cable Compounds | 200-400 | 500-800 | 800-1500 |

| High Concentrated Color MB | 150-350 | 400-700 | 700-1200 |

| Carbon Black MB | 150-350 | 400-700 | 700-1200 |

| High Loaded Filler MB | 200-400 | 600-1000 | 900-1600 |

| Fiber MB | 150-350 | 400-700 | 700-1200 |

Layout for HFFR working process

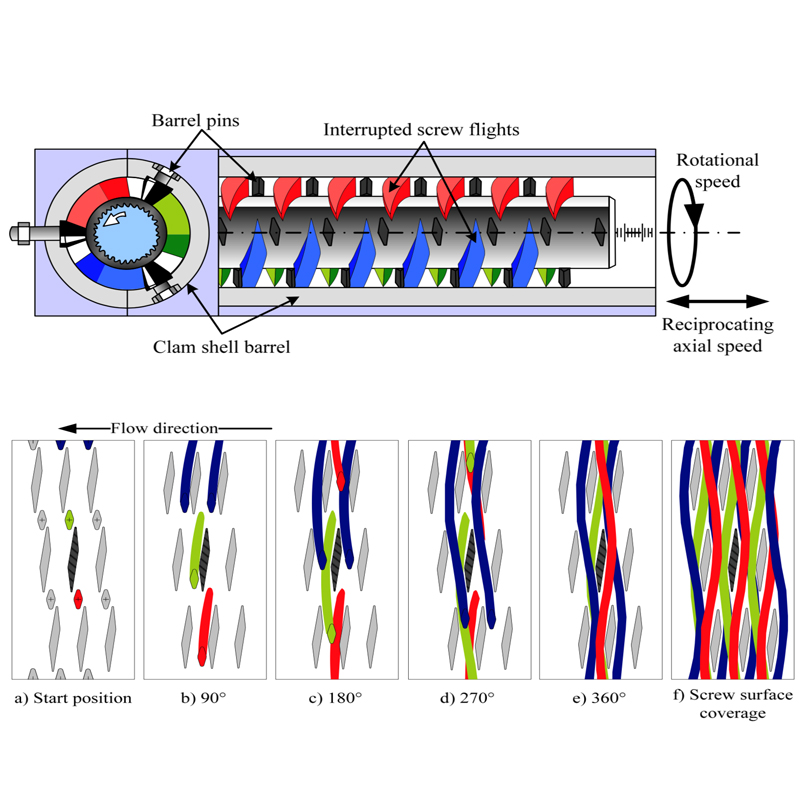

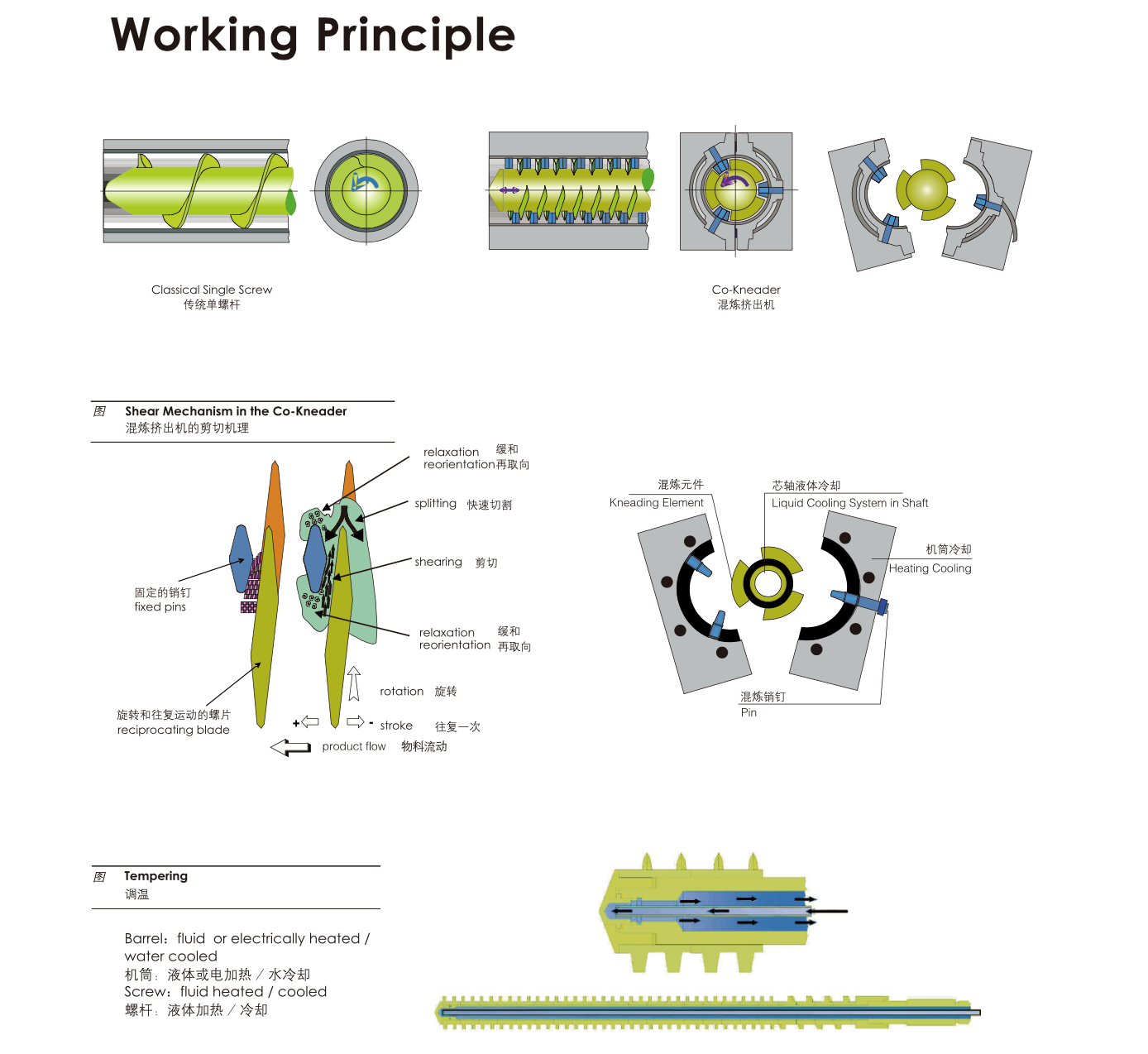

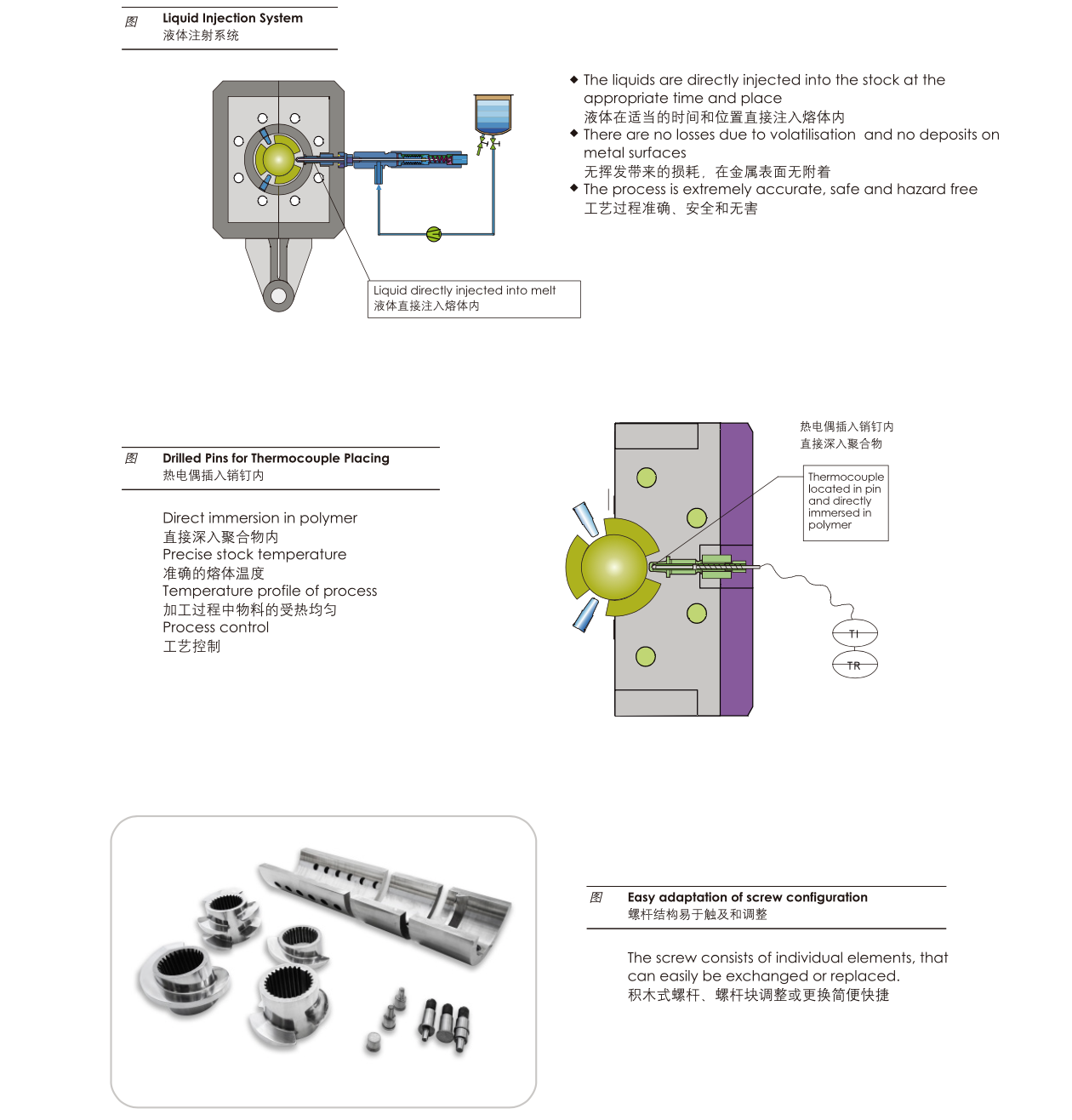

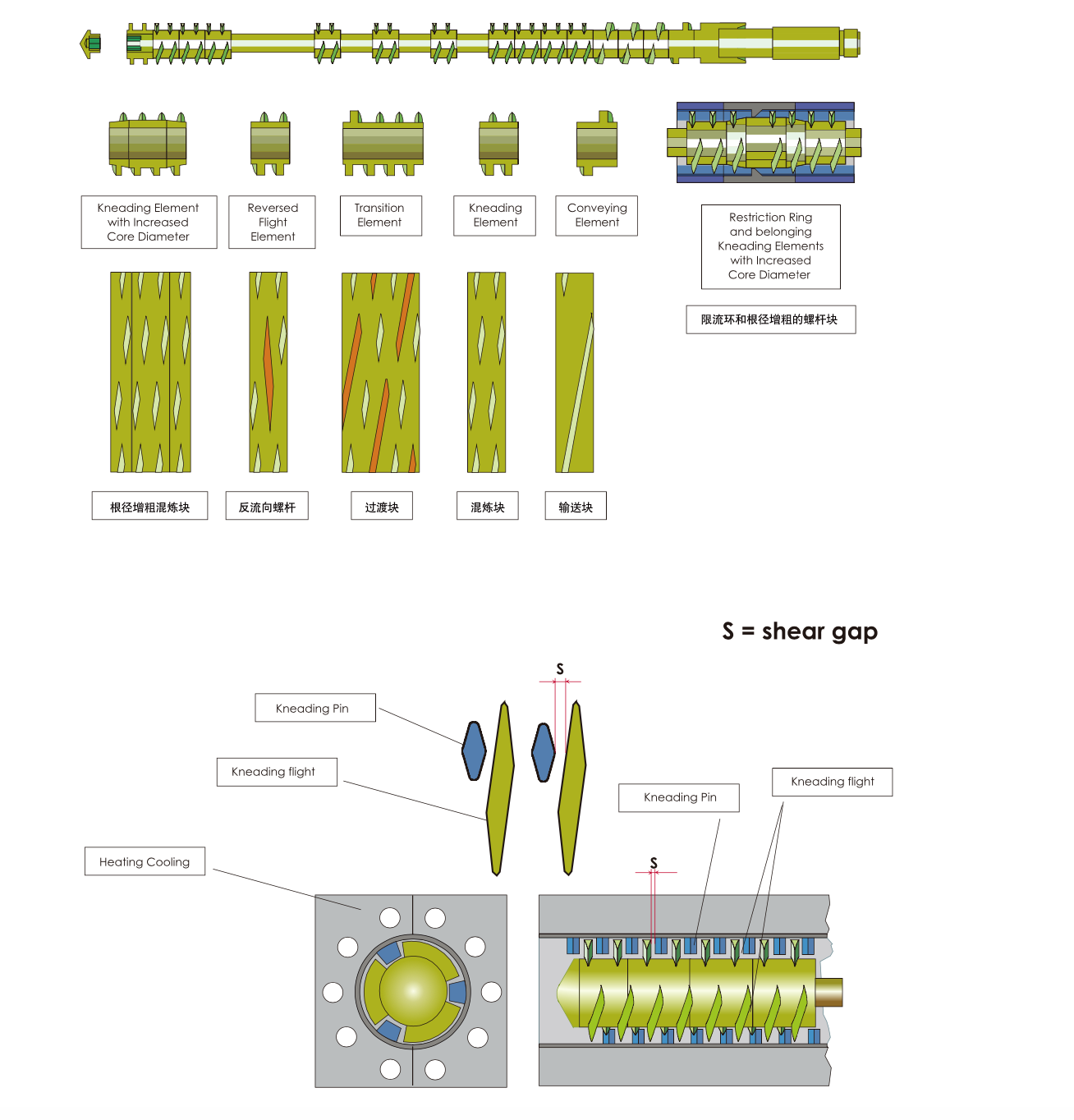

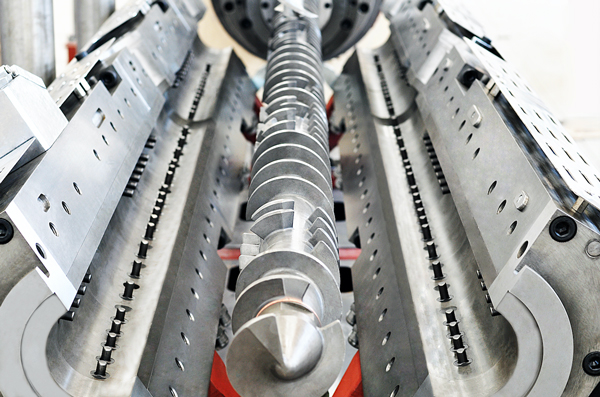

Working Principle For Co-kneader

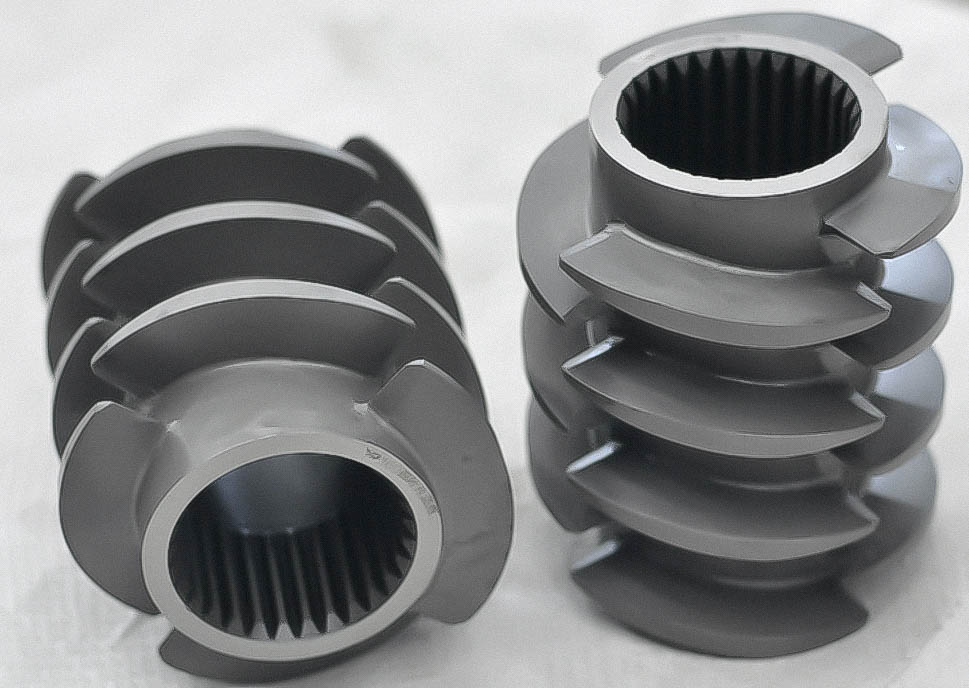

Advantage For Four Flights Co-kneader

Feature

Feature

- Lower energy input, lower melt temperatures

- Extremely homogeneous mixing, no shear spikes, equal treatment of polymer matrix

- High degree of self-wiping and have no dead spot

- Dispersive mixing without destroying delicate fllers

- High volumetric loadings of fllers and additives

- Efficient blending of liquid components

- Broad application for compounding without changing hardware

- Axially opened split barrel guarantees ease of cleaning and fast maintenance

- Replacement parts, such as screws, barrel lining and pins can be changed individually

Factory Introduction

Application of the Twin Screw Extruder:

- Various plastic inorganic filler, polymer blending (plastic alloy), plastic coloring, ect

- Various engineering plastic reinforcement of glass fiber, flame-retartant pellets

- Various antibacterial, insulated, toughening materials for specific uses

- Light/biology degradable film materials, amylum degradable plastics and multi-functional anti-fog film materials, etc.

- Specific material for automobiles and household appliance and cable materials, etc

- Themoplastic elastomers, such as TPR, TPE, and SBS, etc

- Regenerate pellets for PVC airproof pieces, thermo-soluble glue, etc

|

Model

|

PSHJ-20

|

PSHJ-35

|

PSHJ-50

|

PSHJ-65

|

PSHJ-75

|

PSHJ-127

|

|

Screw Diameter:

MM |

21.7

|

35.6

|

50.5

|

62.4

|

71

|

126

|

|

Central Distance

|

18

|

30

|

42

|

52

|

60

|

102

|

|

Length Diameter Ratio

|

28-52

|

28-52

|

28-52

|

28-52

|

28-52

|

28-52

|

|

Main Motor Power

|

4-5.5

|

22-45

|

75-110

|

110-185

|

160-280

|

90-160

|

|

Max.Screw Speed:

RPM |

600

|

600

|

600

|

600

|

600

|

600

|

|

Output Torque per Shaft:N.m

|

32-43

|

175-358

|

597-875

|

875-1472

|

1273-2228

|

850-1528

|

|

Reference Output: KG/HOUR

|

5-20

|

20-80

|

80-200

|

150-350

|

300-600

|

800-1500

|

|

Max.Screw Speed:

RPM |

800

|

800

|

800

|

800

|

500

|

|

Model

|

C-PSHJ-35

|

C-PSHJ-50

|

C-PSHJ-65

|

C-PSHJ-75

|

C-PSHJ-127

|

|

Screw Diameter:

MM |

35.6

|

50.5

|

62.4

|

71

|

126

|

|

Central Distance

|

30

|

42

|

52

|

60

|

102

|

|

Length Diameter Ratio

|

28-52

|

28-52

|

28-52

|

28-52

|

13-18

|

|

Main Motor Power

|

22-45

|

75-132

|

110-250

|

160-355

|

90-160

|

|

Output Torque per Shaft:N.m

|

131-269

|

448-788

|

657-1492

|

955-2119

|

850-1528

|

|

Reference Output: KG/HOUR

|

150-300

|

200-500

|

400-800

|

500-100

|

800-1500

|